- CRUSHING AND SIZING

- GRINDING AND MILLING

- CALCINING AND ROASTING

- PYRO

- CONVEYOR

-

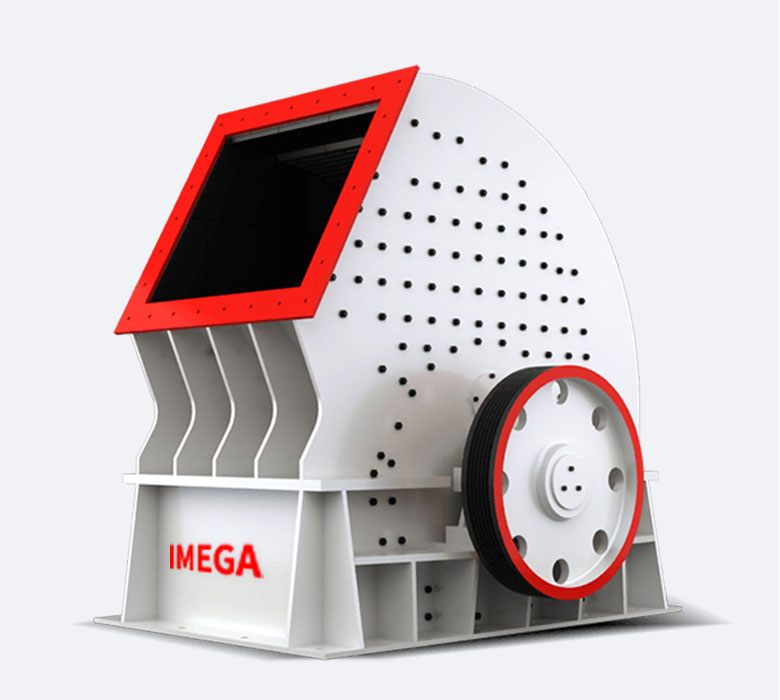

HAMMER CRUSHER

Equipment introduction:

The spring cone crusher design is able to pass uncrush able materials e.g. tramp metal, through the crushing cavity by using springs.

The first hydraulic cone crusher was developed in 1948 and this allowed for the opening of the crushing cavity hydraulically, instead of using springs (mechanical actuation).

Read More

JAW CRUSHER

Equipment introduction:

The spring cone crusher design is able to pass uncrush able materials e.g. tramp metal, through the crushing cavity by using springs.

The first hydraulic cone crusher was developed in 1948 and this allowed for the opening of the crushing cavity hydraulically, instead of using springs (mechanical actuation).

Read More

CONCENTRATING

Equipment introduction:

The spring cone crusher design is able to pass uncrush able materials e.g. tramp metal, through the crushing cavity by using springs.

The first hydraulic cone crusher was developed in 1948 and this allowed for the opening of the crushing cavity hydraulically, instead of using springs (mechanical actuation).

Read More

-

VERTICAL ROLLER MILL

Equipment introduction:

The spring cone crusher design is able to pass uncrush able materials e.g. tramp metal, through the crushing cavity by using springs.

The first hydraulic cone crusher was developed in 1948 and this allowed for the opening of the crushing cavity hydraulically, instead of using springs (mechanical actuation).

Read More

BALL MILL

Equipment introduction:

The spring cone crusher design is able to pass uncrush able materials e.g. tramp metal, through the crushing cavity by using springs.

The first hydraulic cone crusher was developed in 1948 and this allowed for the opening of the crushing cavity hydraulically, instead of using springs (mechanical actuation).

Read More

RAYMOND MILL

Equipment introduction:

The spring cone crusher design is able to pass uncrush able materials e.g. tramp metal, through the crushing cavity by using springs.

The first hydraulic cone crusher was developed in 1948 and this allowed for the opening of the crushing cavity hydraulically, instead of using springs (mechanical actuation).

Read More

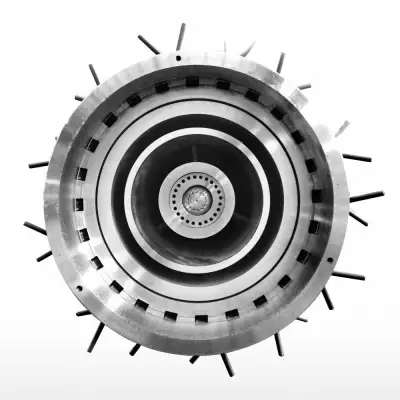

GRINDING MEDIA BALL

Equipment introduction:

The spring cone crusher design is able to pass uncrush able materials e.g. tramp metal, through the crushing cavity by using springs.

The first hydraulic cone crusher was developed in 1948 and this allowed for the opening of the crushing cavity hydraulically, instead of using springs (mechanical actuation).

Read More

-

PREHEATER

Equipment introduction:

The spring cone crusher design is able to pass uncrush able materials e.g. tramp metal, through the crushing cavity by using springs.

The first hydraulic cone crusher was developed in 1948 and this allowed for the opening of the crushing cavity hydraulically, instead of using springs (mechanical actuation).

Read More

CALCINER

Equipment introduction:

The spring cone crusher design is able to pass uncrush able materials e.g. tramp metal, through the crushing cavity by using springs.

The first hydraulic cone crusher was developed in 1948 and this allowed for the opening of the crushing cavity hydraulically, instead of using springs (mechanical actuation).

Read More

-

BURNER

Equipment introduction:

The spring cone crusher design is able to pass uncrush able materials e.g. tramp metal, through the crushing cavity by using springs.

The first hydraulic cone crusher was developed in 1948 and this allowed for the opening of the crushing cavity hydraulically, instead of using springs (mechanical actuation).

Read More

GREAT COOLER

Equipment introduction:

The spring cone crusher design is able to pass uncrush able materials e.g. tramp metal, through the crushing cavity by using springs.

The first hydraulic cone crusher was developed in 1948 and this allowed for the opening of the crushing cavity hydraulically, instead of using springs (mechanical actuation).

Read More

REFRACTORY AND CASTABLE

Equipment introduction:

The spring cone crusher design is able to pass uncrush able materials e.g. tramp metal, through the crushing cavity by using springs.

The first hydraulic cone crusher was developed in 1948 and this allowed for the opening of the crushing cavity hydraulically, instead of using springs (mechanical actuation).

Read More

-

BUCKET ELEVATOR

Equipment introduction:

The spring cone crusher design is able to pass uncrush able materials e.g. tramp metal, through the crushing cavity by using springs.

The first hydraulic cone crusher was developed in 1948 and this allowed for the opening of the crushing cavity hydraulically, instead of using springs (mechanical actuation).

Read More

PAN CONVEYOR

Equipment introduction:

The spring cone crusher design is able to pass uncrush able materials e.g. tramp metal, through the crushing cavity by using springs.

The first hydraulic cone crusher was developed in 1948 and this allowed for the opening of the crushing cavity hydraulically, instead of using springs (mechanical actuation).

Read More

BELT CONVEYOR

Equipment introduction:

The spring cone crusher design is able to pass uncrush able materials e.g. tramp metal, through the crushing cavity by using springs.

The first hydraulic cone crusher was developed in 1948 and this allowed for the opening of the crushing cavity hydraulically, instead of using springs (mechanical actuation).

Read More

CHAIN CONVEYOR

Equipment introduction:

The spring cone crusher design is able to pass uncrush able materials e.g. tramp metal, through the crushing cavity by using springs.

The first hydraulic cone crusher was developed in 1948 and this allowed for the opening of the crushing cavity hydraulically, instead of using springs (mechanical actuation).

Read More